Engineering Excellence in Modern Honeycomb Bag Construction

The evolution of packaging solutions has led to remarkable innovations in honeycomb bags, transforming them from simple containers into highly engineered products. These sophisticated storage solutions combine advanced materials science with precision design to create exceptionally durable packaging options. Understanding the key design elements that enhance their longevity and performance is crucial for industries relying on robust packaging solutions.

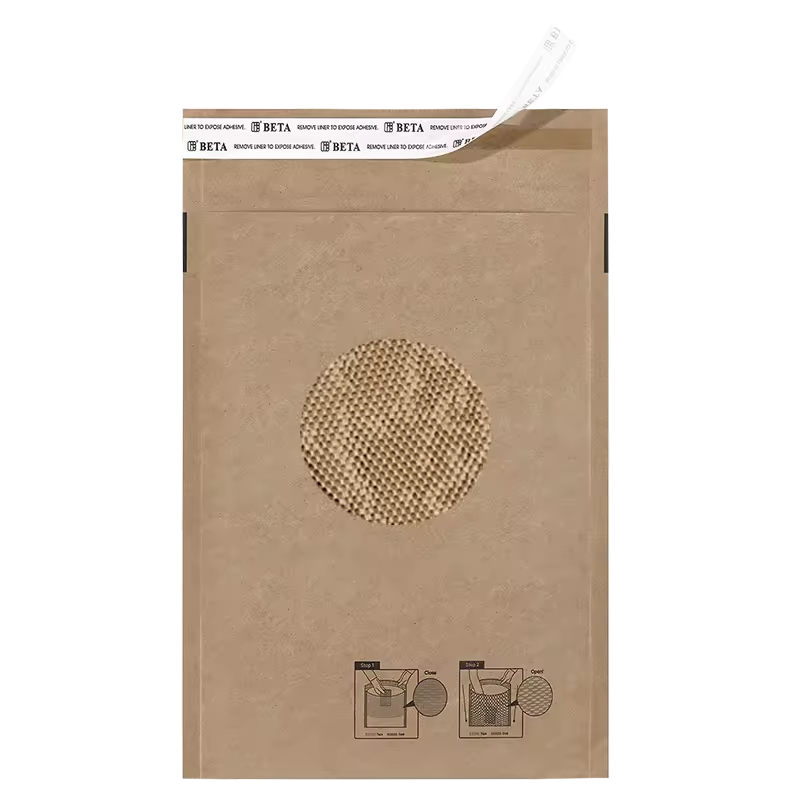

Modern honeycomb bags represent a significant leap forward in packaging technology, incorporating multiple layers of protection and structural support. Their unique construction draws inspiration from nature's most efficient structure - the honeycomb pattern - while utilizing cutting-edge materials and manufacturing processes to maximize strength and durability.

Structural Components and Material Selection

Advanced Material Composition

The foundation of durable honeycomb bags begins with carefully selected materials. High-grade polymers, reinforced fibers, and specialized coating materials work together to create a robust exterior. These materials undergo rigorous testing to ensure they meet specific strength requirements while maintaining flexibility and practical functionality.

Premium honeycomb bags often incorporate multiple layers of different materials, each serving a specific purpose. The outer layer typically features wear-resistant polymers, while inner layers may include moisture barriers and cushioning materials. This multi-layer approach significantly enhances the overall durability and protective capabilities of the bag.

Strategic Reinforcement Placement

Strategic reinforcement points are crucial in extending the lifespan of honeycomb bags. High-stress areas, such as corners, handles, and base sections, receive additional reinforcement through double-layering or specialized strengthening techniques. These reinforced zones prevent common failure points and ensure the bag maintains its structural integrity even under heavy loads.

The placement of support structures follows careful analysis of usage patterns and stress distribution. Modern designs incorporate reinforced seams, specialized stitching patterns, and strategic support placement to create a balanced distribution of forces throughout the bag's structure.

Innovative Design Elements

Geometric Optimization

The honeycomb pattern itself represents a marvel of geometric efficiency. When properly implemented in bag design, this structure provides exceptional strength-to-weight ratios and superior load distribution. Advanced manufacturing processes ensure precise hexagonal patterns that maximize structural integrity while minimizing material usage.

Engineers continuously refine the dimensions and arrangement of honeycomb cells to achieve optimal performance. The size, depth, and orientation of these cells significantly impact the bag's overall durability and load-bearing capacity. Modern designs often feature variable cell sizes, with smaller cells in high-stress areas and larger cells where additional flexibility is beneficial.

Smart Stress Distribution Systems

Contemporary honeycomb bags incorporate innovative stress distribution systems that prevent localized damage from compromising the entire structure. These systems include carefully designed load-bearing paths, strategic fold lines, and integrated support networks that work together to maintain the bag's shape and integrity under various conditions.

The implementation of smart stress distribution involves sophisticated computer modeling and real-world testing to identify and address potential weak points. This approach results in bags that can withstand significant physical stress while maintaining their protective properties.

Protective Features and Coatings

Environmental Defense Mechanisms

Modern honeycomb bags feature advanced protective coatings that shield against environmental factors. These treatments provide resistance to UV radiation, moisture, and temperature variations while maintaining the bag's structural properties. Specialized surface treatments can also enhance chemical resistance and prevent material degradation over time.

The latest coating technologies offer multiple layers of protection without adding significant weight or bulk to the bag. These innovations include self-healing surfaces, hydrophobic treatments, and anti-static properties that contribute to extended service life.

Impact Absorption Technology

Superior impact resistance is achieved through carefully designed absorption zones within the honeycomb structure. These areas compress and deform in a controlled manner to dissipate impact energy, protecting both the bag and its contents. The integration of specialized impact-absorbing materials in critical areas further enhances this protective capability.

Modern designs often incorporate dynamic response systems that adapt to different types of impacts, providing comprehensive protection against both sudden shocks and sustained pressure. This adaptability is crucial for maintaining the bag's integrity during various handling and transportation scenarios.

Maintenance and Longevity Features

Self-Maintaining Properties

Advanced honeycomb bags often include self-maintaining features that help preserve their structural integrity. These can include self-aligning components, memory materials that retain their shape, and surfaces that resist wear and accumulation of debris. Such features significantly reduce maintenance requirements while extending service life.

The incorporation of smart materials that respond to environmental conditions helps maintain optimal performance throughout the bag's lifecycle. These innovations represent a significant advance in creating truly sustainable packaging solutions.

Repair and Replacement Considerations

Modern design approaches consider the eventual need for repairs or component replacement. Modular construction methods allow for the easy replacement of worn sections without compromising the entire structure. This forward-thinking approach extends the practical lifespan of honeycomb bags while reducing waste and replacement costs.

Strategic placement of wear indicators and maintenance access points facilitates timely interventions, preventing minor issues from developing into major structural problems. This preventive approach significantly contributes to the long-term durability of the bags.

Frequently Asked Questions

What makes honeycomb bags more durable than traditional packaging?

Honeycomb bags derive their superior durability from their unique geometric structure, advanced materials, and strategic reinforcement placement. The honeycomb pattern provides exceptional strength while distributing forces evenly across the entire structure, preventing localized damage and extending overall lifespan.

How long can a well-designed honeycomb bag last?

The lifespan of a properly designed honeycomb bag typically ranges from 3-5 years under normal use conditions. However, bags incorporating advanced protective features and receiving proper maintenance can last significantly longer, sometimes exceeding 7-10 years of service life.

What environmental factors most affect honeycomb bag durability?

The primary environmental factors affecting honeycomb bag durability include UV exposure, moisture, temperature fluctuations, and chemical exposure. Modern protective coatings and materials are specifically designed to combat these factors, significantly extending the bag's useful life in challenging environments.

How can users maximize the lifespan of their honeycomb bags?

To maximize longevity, users should follow proper loading guidelines, avoid exposure to extreme environmental conditions, conduct regular inspections for wear, and address any damage promptly. Proper storage and handling practices, combined with routine maintenance, can significantly extend the service life of honeycomb bags.