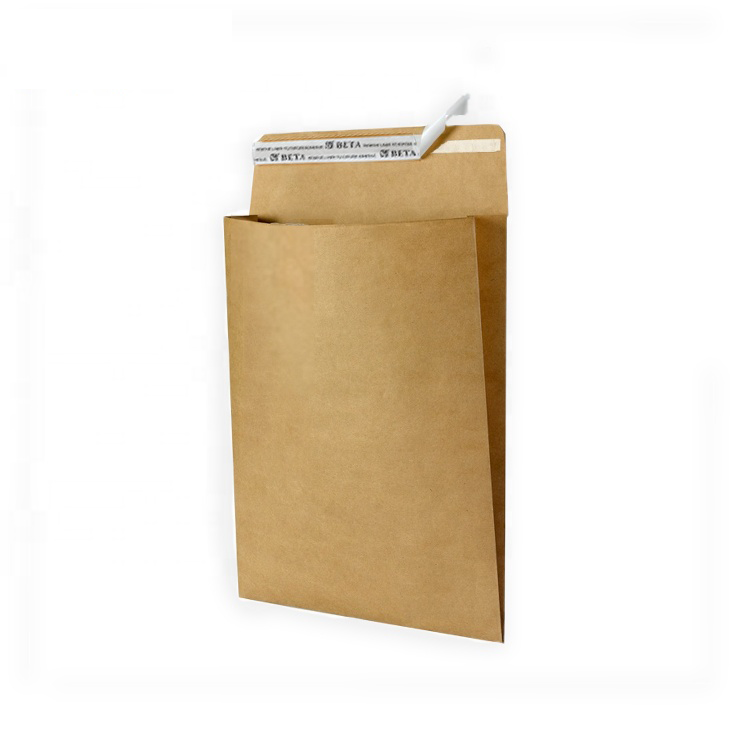

anpassade förpackningspåsar

Anpassade förpackningspåsar representerar en mångsidig och viktig lösning inom modern förpackning, som kombinerar funktionalitet med varumärkesuttryck. Dessa särskilt designade behållare är tillverkade för att uppfylla specifika produktkrav och erbjuder skydd, bevarande och promoriondalsvärde. Påsarna använder avancerade tillverkningsteknologier, inklusive flerlagersfilmsstrukturer, högbarriärmaterial och precisionstrycktekniker, vilket säkerställer optimal produktbevarelse och visuell attraktivitet. De kan produceras i olika storlekar, former och material, från flexibla plaster till ekologiska biologiskt nedbrytbara alternativ, för att möta olika branschbehov. Påsarna har anpassningsbara element som återförslutningsdragkedjor, ståendefunktion och särskilda beläggningstekniker för förbättrad hållbarhet. De integrerar avancerade tryckteknologier som möjliggör högupplösta bilder, varumärkesloggor och produktinformation, vilket skapar ett starkt utseende i hyllan. Dessa förpackningslösningar inkluderar ofta praktiska funktioner som revsnitt, handtag och genomskinliga fönster, vilket förbättrar användarupplevelsen utan att kompromissa med produktens integritet. Påsarna är konstruerade för att uppfylla specifika branschstandarder och regler, särskilt inom livsmedels-, läkemedels- och detaljhandelssektorer, för att säkerställa efterlevnad och säkerhet.