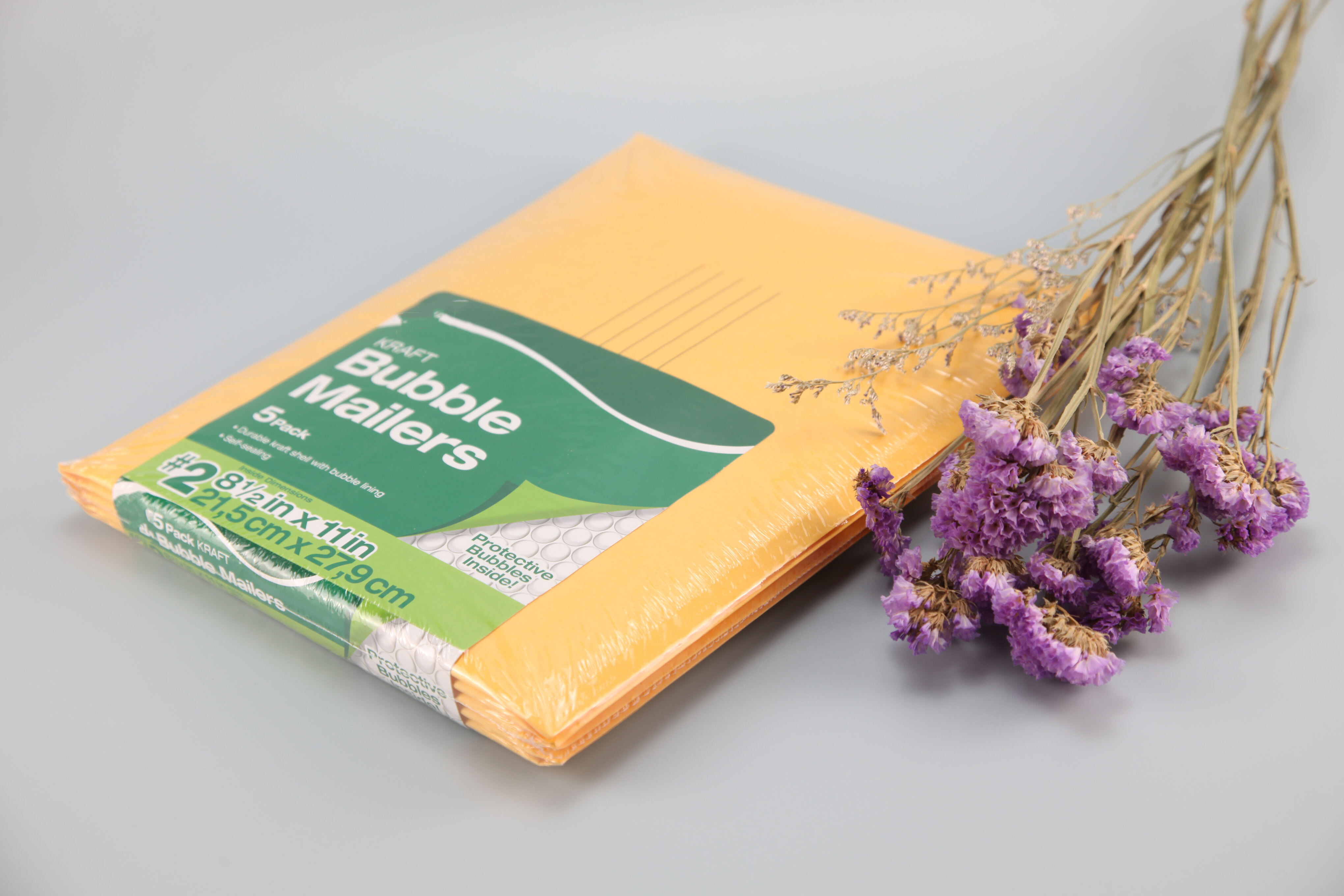

In today's fast-paced e-commerce landscape, businesses face the critical challenge of ensuring their products reach customers safely while maintaining cost-effectiveness. Kraft bubble mailers have emerged as the preferred packaging solution for lightweight and fragile items, combining superior protection with environmental responsibility. These innovative shipping envelopes offer a perfect balance of durability, cushioning, and sustainability that modern businesses demand.

The rise in online shopping has created unprecedented demand for packaging that protects delicate merchandise during transit. Traditional cardboard boxes often prove excessive for small, lightweight items, leading to increased shipping costs and environmental waste. Meanwhile, standard envelopes provide insufficient protection for fragile products. This gap in the market has positioned kraft bubble mailers as the optimal solution, bridging functionality with ecological consciousness.

Understanding why businesses increasingly choose these specialized mailers requires examining their unique construction, protective capabilities, and environmental benefits. From electronics retailers to jewelry manufacturers, companies across various industries have discovered that kraft bubble mailers offer unmatched value for their specific shipping needs. The combination of kraft paper exterior and bubble cushioning interior creates a packaging solution that addresses multiple concerns simultaneously.

Superior Protection Through Advanced Design

Multi-Layer Construction Benefits

The engineering behind kraft bubble mailers represents a significant advancement in protective packaging technology. The outer kraft paper layer provides tear resistance and structural integrity, while the inner bubble lining offers exceptional shock absorption. This dual-layer system creates a protective barrier that significantly reduces the risk of damage during handling and transportation.

The bubble cushioning component utilizes strategically sized air pockets that compress upon impact, distributing force evenly across the surface. This mechanism prevents concentrated pressure points that could damage fragile items. The kraft paper exterior adds an additional layer of protection against punctures, moisture, and external contaminants that could compromise product integrity.

Professional packaging engineers have conducted extensive testing to optimize the bubble density and kraft paper thickness ratios. These calculations ensure maximum protection while maintaining lightweight characteristics essential for cost-effective shipping. The result is a mailer that can withstand typical shipping stresses while adding minimal weight to the overall package.

Impact Resistance and Cushioning Properties

The cushioning effectiveness of kraft bubble mailers stems from their ability to absorb and dissipate kinetic energy during impacts. When packages experience drops, compressions, or collisions during transit, the bubble layer immediately responds by compressing and redistributing the force. This reaction prevents sudden jolts from reaching the enclosed products.

Laboratory testing demonstrates that quality kraft bubble mailers can protect items from drops of up to six feet, which exceeds typical shipping handler scenarios. The bubble size optimization ensures that smaller fragile components, such as electronic circuits or delicate accessories, receive adequate protection without excessive bulk. This precision in protective design makes them ideal for items that require gentle handling.

The self-sealing adhesive strips commonly integrated into kraft bubble mailers provide secure closure without compromising the protective envelope. This feature eliminates the need for additional tape or sealing materials, reducing packaging time while maintaining tamper-evident security throughout the shipping process.

Cost-Effectiveness and Shipping Efficiency

Weight Reduction Advantages

Shipping costs directly correlate with package weight and dimensions, making kraft bubble mailers an economically attractive option for businesses. These mailers typically weigh 60-70% less than equivalent cardboard boxes while providing comparable protection levels. This weight reduction translates to substantial savings in shipping expenses, particularly for high-volume shippers.

The lightweight nature of kraft bubble mailers allows businesses to maximize their shipping cost efficiency without sacrificing product protection. E-commerce companies shipping thousands of items monthly can achieve significant cost reductions by switching from heavier packaging alternatives. The cumulative savings often justify the initial investment in quality mailers within the first few months of implementation.

Dimensional weight calculations, used by major shipping carriers, favor the compact profile of kraft bubble mailers. These mailers conform closely to product shapes, minimizing excess space that contributes to higher shipping classifications. Smart businesses leverage this characteristic to optimize their logistics costs while maintaining professional presentation standards.

Storage and Handling Efficiency

Warehouse management becomes significantly more efficient when utilizing kraft bubble mailers due to their stackable, flat-pack design. Unlike bulky cardboard boxes that consume considerable storage space, these mailers can be stored in compact quantities, reducing warehouse footprint requirements. This space efficiency allows businesses to maintain larger inventory levels within existing storage facilities.

The pre-formed nature of kraft bubble mailers eliminates assembly time required for traditional packaging solutions. Workers can quickly insert products and seal packages without folding, taping, or constructing boxes. This streamlined process reduces labor costs and increases packaging throughput, particularly beneficial during peak shipping seasons when efficiency becomes critical.

Quality kraft bubble mailers feature consistent dimensions that facilitate automated packaging processes. Businesses utilizing packaging machinery can program specific settings for these standardized mailers, enabling high-speed processing without manual adjustments. This automation capability represents a significant operational advantage for companies processing large volumes of shipments.

Environmental Sustainability Features

Recyclable Material Composition

Environmental consciousness has become a crucial factor in packaging decisions, and kraft bubble mailers address sustainability concerns through their recyclable material composition. The kraft paper component derives from renewable wood sources and can be processed through standard paper recycling streams. This recyclability aligns with corporate sustainability initiatives and consumer environmental expectations.

Modern manufacturing processes for kraft bubble mailers increasingly utilize recycled content in both the paper and plastic bubble components. Some manufacturers achieve up to 70% recycled content while maintaining protective performance standards. This approach reduces demand for virgin materials and supports circular economy principles that many businesses now prioritize.

The biodegradable nature of kraft paper ensures that even if mailers end up in landfills, they break down naturally over time. This characteristic contrasts favorably with purely plastic packaging alternatives that persist in the environment for decades. Companies can confidently promote their environmental responsibility when choosing kraft bubble mailers for their shipping needs.

Reduced Carbon Footprint Impact

The production process for kraft bubble mailers generates significantly lower carbon emissions compared to equivalent cardboard box manufacturing. The simplified construction requires less energy-intensive processing and fewer transportation resources for raw materials. This reduced carbon footprint appeals to environmentally conscious businesses seeking to minimize their ecological impact.

Transportation efficiency gains from using lightweight kraft bubble mailers extend beyond direct shipping costs to environmental benefits. Reduced package weights allow shipping vehicles to carry more items per trip, decreasing fuel consumption and associated emissions. This multiplier effect contributes to overall carbon footprint reduction across the entire supply chain.

Many kraft bubble mailer manufacturers have implemented renewable energy sources in their production facilities, further reducing the environmental impact of these packaging solutions. Solar and wind power integration in manufacturing processes demonstrates the industry's commitment to sustainable production methods that align with broader environmental objectives.

Industry-Specific Applications

Electronics and Technology Products

The electronics industry has embraced kraft bubble mailers as an ideal packaging solution for small consumer devices, accessories, and components. Mobile phone cases, charging cables, and electronic accessories benefit from the anti-static properties available in specialized kraft bubble mailers. These properties prevent electrostatic discharge that could damage sensitive electronic components during shipping.

Computer hardware manufacturers utilize kraft bubble mailers for shipping items such as memory modules, small peripherals, and replacement parts. The cushioning properties protect delicate circuit boards and connectors while the moisture-resistant kraft paper exterior prevents humidity-related damage. This dual protection proves essential for maintaining product functionality and reducing return rates.

Telecommunications companies shipping SIM cards, adapter cables, and small networking devices find kraft bubble mailers provide optimal protection-to-cost ratios. The professional appearance of quality kraft mailers enhances brand perception while ensuring products arrive in perfect condition. This balance of functionality and presentation supports customer satisfaction and brand reputation.

Fashion and Textile Applications

Fashion retailers have discovered that kraft bubble mailers offer excellent protection for clothing items, accessories, and textile products while maintaining an environmentally conscious brand image. The tear-resistant kraft exterior prevents snagging during handling, while the bubble interior prevents compression wrinkles that could affect product presentation upon delivery.

Jewelry manufacturers and retailers particularly value kraft bubble mailers for their ability to protect delicate items without excessive packaging bulk. The cushioning properties prevent movement within the package that could cause scratching or tangling of chains and delicate components. The secure sealing mechanism ensures valuable items remain protected throughout the shipping process.

Cosmetic and personal care product manufacturers utilize kraft bubble mailers for shipping small containers, tubes, and delicate packaging that requires protection from crushing or impact damage. The moisture-resistant properties help maintain product integrity, while the professional appearance supports premium brand positioning in competitive markets.

Quality Standards and Selection Criteria

Material Specifications and Testing

Professional-grade kraft bubble mailers undergo rigorous testing to ensure consistent protective performance across various shipping conditions. Drop testing simulates real-world handling scenarios, while compression testing evaluates the mailers' ability to maintain protective properties under stacking loads. These standardized tests provide measurable data for comparing different mailer options.

The kraft paper component should meet specific tear strength and puncture resistance standards to ensure reliable protection during transit. Industry-standard testing methods evaluate these characteristics under controlled conditions, providing objective criteria for quality assessment. Businesses should specify minimum performance requirements when sourcing kraft bubble mailers for their applications.

Adhesive strength testing ensures that self-sealing strips maintain secure closure throughout the shipping process without premature failure or difficulty in opening. Temperature variation testing confirms that adhesive performance remains consistent across different climate conditions that packages may encounter during transportation. These quality standards directly impact customer satisfaction and product protection reliability.

Size Selection and Customization Options

Proper size selection for kraft bubble mailers directly influences both protection effectiveness and shipping cost optimization. Mailers should provide sufficient space for products while minimizing excess void fill requirements. The ideal fit allows minimal movement within the package while avoiding compression that could damage contents or compromise protective properties.

Customization options for kraft bubble mailers include printing capabilities that support branding and professional presentation. High-quality printing on kraft surfaces enables companies to incorporate logos, handling instructions, and promotional messages while maintaining the protective benefits of the underlying mailer construction. This customization capability supports marketing objectives alongside shipping functionality.

Specialized features such as tamper-evident seals, tear strips for easy opening, and reinforced sealing areas address specific industry requirements. Medical device manufacturers, for example, may require tamper-evident features to ensure product integrity, while consumer goods companies might prioritize easy-opening designs that enhance customer experience.

FAQ

What makes kraft bubble mailers more suitable for fragile items than regular envelopes?

Kraft bubble mailers incorporate a dual-layer protection system combining tear-resistant kraft paper with bubble cushioning, providing superior impact protection compared to regular envelopes. The bubble layer absorbs shocks and prevents damage from drops or compressions during shipping, while the kraft exterior offers additional puncture and moisture resistance that standard envelopes cannot provide.

Are kraft bubble mailers environmentally friendly compared to other packaging options?

Yes, kraft bubble mailers offer significant environmental advantages through their recyclable kraft paper component and reduced material usage compared to cardboard boxes. Many manufacturers use recycled content in production, and the lightweight design reduces transportation-related carbon emissions. The kraft paper portion biodegrades naturally, making these mailers a more sustainable choice for environmentally conscious businesses.

How do kraft bubble mailers help reduce shipping costs for businesses?

Kraft bubble mailers reduce shipping costs through their lightweight construction, which can be 60-70% lighter than equivalent cardboard packaging while providing comparable protection. Their compact profile minimizes dimensional weight calculations used by carriers, and their conforming design reduces excess space that contributes to higher shipping classifications. Additionally, they require less storage space and faster packaging processes, reducing operational costs.

What size range is available for kraft bubble mailers and how should businesses choose the right size?

Kraft bubble mailers are available in sizes ranging from small 4x8 inch options for jewelry and small electronics to large 19x24 inch mailers for documents and soft goods. Businesses should select sizes that allow minimal product movement while avoiding compression, typically choosing mailers 1-2 inches larger than the product dimensions in each direction. Proper sizing ensures optimal protection while minimizing shipping costs and material waste.

Table of Contents

- Superior Protection Through Advanced Design

- Cost-Effectiveness and Shipping Efficiency

- Environmental Sustainability Features

- Industry-Specific Applications

- Quality Standards and Selection Criteria

-

FAQ

- What makes kraft bubble mailers more suitable for fragile items than regular envelopes?

- Are kraft bubble mailers environmentally friendly compared to other packaging options?

- How do kraft bubble mailers help reduce shipping costs for businesses?

- What size range is available for kraft bubble mailers and how should businesses choose the right size?