korrugerade Mailers

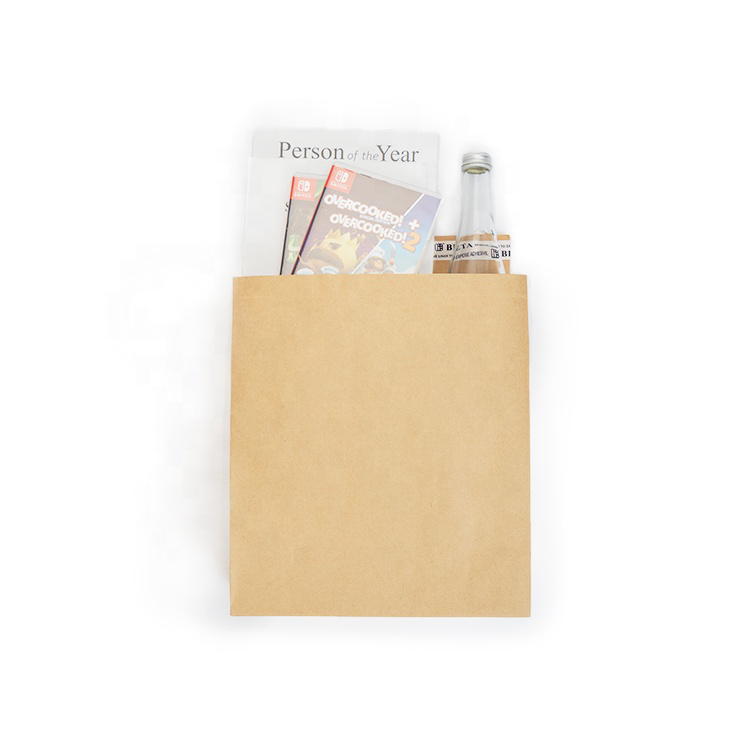

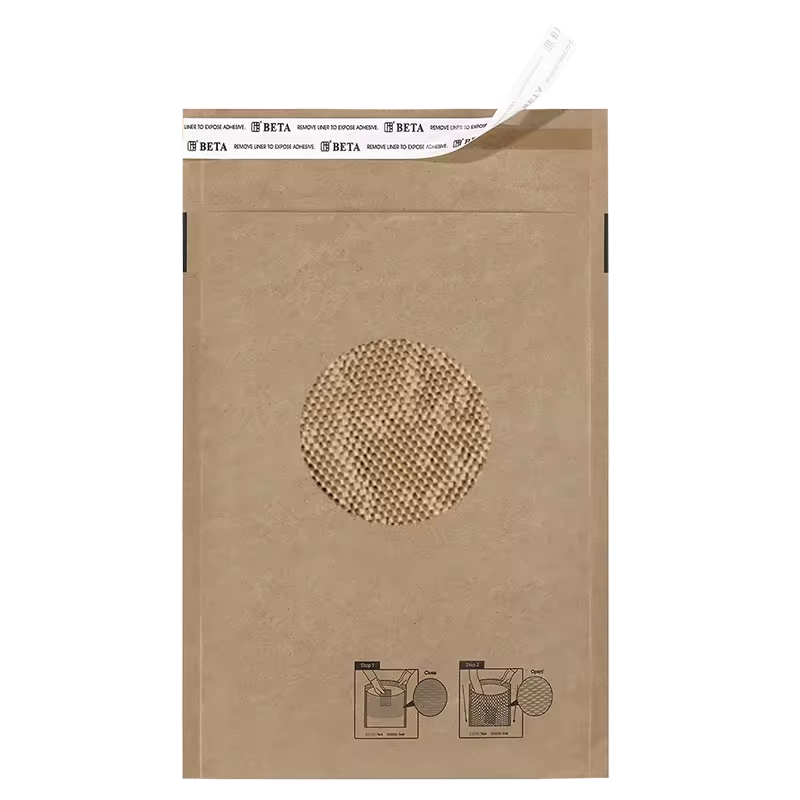

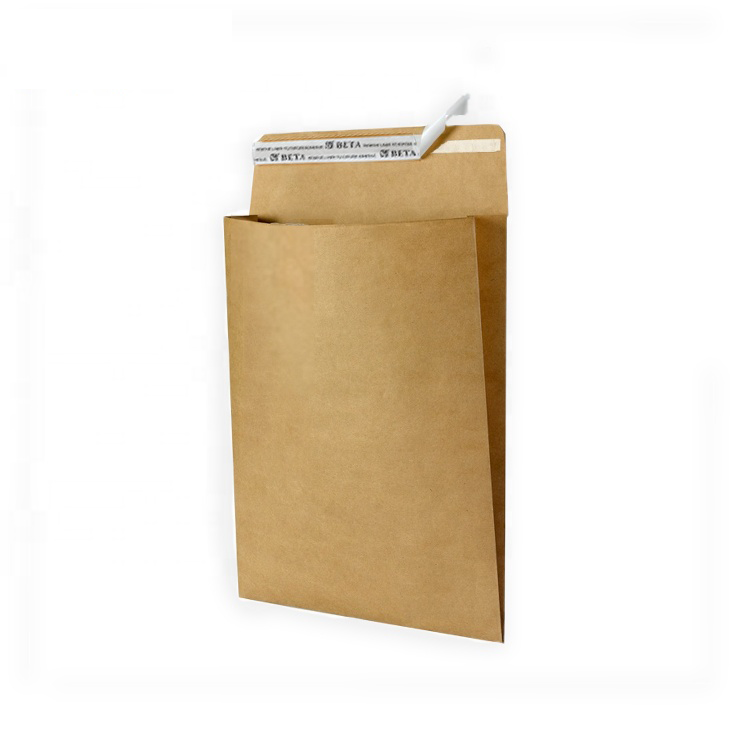

Vågformade kuvert utgör en revolutionerande utveckling inom förpackningslösningar, där hållbarhet kombineras med praktisk design. Dessa transportbehållare är uppbyggda av flera lager flikat kartongmaterial som är insprängt mellan platta pappskivor, vilket skapar en robust struktur som skyddar innehållet under transport. Den unika vågformade strukturen i det flikade materialet ger utmärkt dämpning och strukturell stabilitet samtidigt som den behåller en lättviktsprofil. Dessa kuvert är noggrant konstruerade för att erbjuda maximal skydd mot stötar, tryck och miljöpåverkan. Designen innehåller användarvänliga funktioner såsom enkel-tätande klistremsar, öppningsremsor för att slita upp och varierande storleksalternativ för att anpassa sig till olika produktdimensioner. Moderna vågformade kuvert innehåller ofta förbättrade egenskaper som vattenavvisande beläggningar, förstärkta hörn och möjlighet till anpassad tryckning. De tillverkas med hjälp av hållbara material, vilket gör dem till ett miljövänligt val för både företag och konsumenter. Användningsområdena för vågformade kuvert är mångsidiga och omfattar olika branscher, från e-handel och detaljhandel till tillverkningsindustri och logistik, och erbjuder pålitligt skydd för allt från känsliga elektronikartiklar till kraftfulla industriella komponenter.